polypropylene packaging and packaging

The enterprise produces soft containers (Big Bags) of a wide variety of types with a carrying capacity of 500, 1000, 1500 kg with a safety factor of 5:1. We carry out a full technological cycle for the production of soft containers, from extrusion of polypropylene yarns and weaving of high-strength fabrics to cutting and tailoring finished products of the most diverse types.

3-color flexoprinting can be applied on the side surface of the container.

Strength characteristics of polypropylene fabric deteriorate under the influence of sunlight . Therefore, the UV stabilizer is added to the fabric, what ensures the shelf life of loaded containers in open areas from 1 to 3 months.

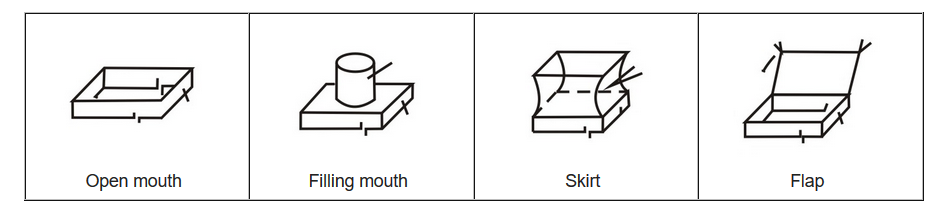

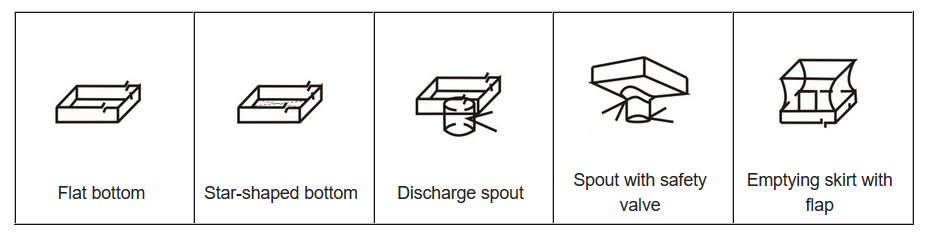

The design of the top and bottom of the container depends on the characteristics of loading and unloading the product and can be performed in such versions:

Design of top: open mouth, filling spout, skirt, flap.

Design of bottom: flat bottom, star-shaped bottom, discharge spout, spout with safety valve, emptying skirt with flap.

Quantity of loops: 1 / 2 / 4

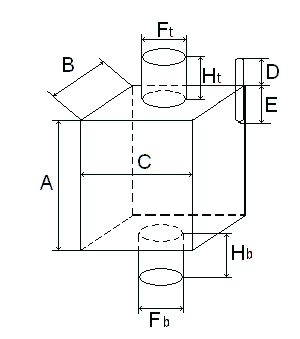

Our equipment allows to make big bags of such sizes:

Our equipment allows to make big bags of such sizes:

| A (height) | 70-200 cm |

| B (length) | 60-110 cm |

| C (width) | 60-110 cm |

| D (working length of loop) | 25-30 cm |

| E (sewn length of loop) | 70% of А (height) |

| F (valve diameter) | 30-35 cm |

| H (valve height) | 35-40 cm |

To make the containers waterproof, they can be made of laminated polypropylene fabric. Density of laminating layer is from 20 to 30 g/m2. Laminate layer is applied by extrusion. Containers made from laminated fabric are used for packing lime, carbon black, marble chips, etc.

Additional protection of the contents of the container can also be ensured by the use of polyethylene liners. Thickness of liner is from 60 to 120 microns, depending on the type of product being loaded. At a high temperature of the product being loaded, heat-resistant liners are used.

In order to place an order for manufacturing you shall fill in the questionnaire!